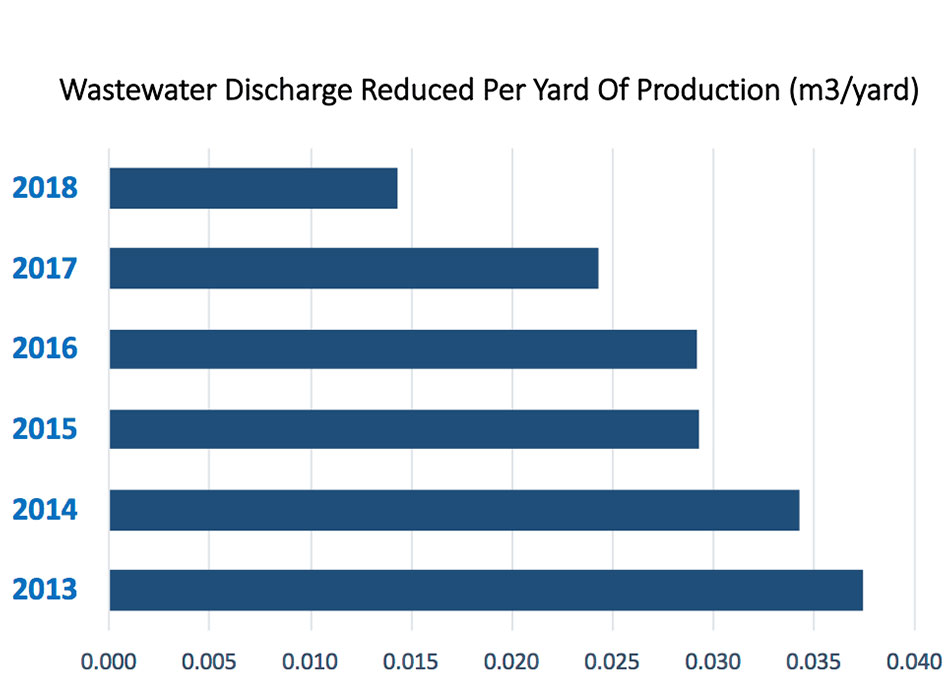

Water

Effluent Treatment Plant to save nature

NDL utilize Effluent Treatment Plant method to purify denim waste water for its reuse. Our aim is to release safe water to environment from the harmful effect caused by the effluent. State of the Art facility with 62 m3 / hour capacity, NDL has taken significant steps to reduce the emission of hazardous chemicals in the environment.

Reuse of Treated wastewater by installing RO plant

Wastewater recycling is an important step at NDL. We have installed RO Plant, so more than 35% of wastewater can be reused in production line, and ground water levels stays well above the national standards.

Reuse of Treated waste water for Plantation & Toilets

NDL in collaboration with WWF-Pakistan has taken steps to Reuse of Treated Waste Water for Plantation & Toilets. More than 10% of Effluent Treated water is being circulated in nearby plants, which will be dramatically increased in coming years.

Reuse of Cooling Cans Water in Finishing Process

Ensuring lowest water utilization and possible, NDL reuse its cooling-can water in denim manufacturing process. Processing 10,000 liters per hour, NDL reapplies water in Sanforizing and Stenter process.

Reuse of Hot Water from Caustic Recovery Unit

12,000 liters per hour hot water is re-used at NDL's Caustic Recovery Unit. Required for mercerizing process, NDL ensures minimum waster wastage and reuses hot water in production of finest quality denim.

Rain Harvesting System (Project)

NDL ensures the ground water level stays well above national standards by using Rain Water in Denim Manufacturing process. Rain water is collected from rooftop, stored and used in various water demanding processes.