Energy

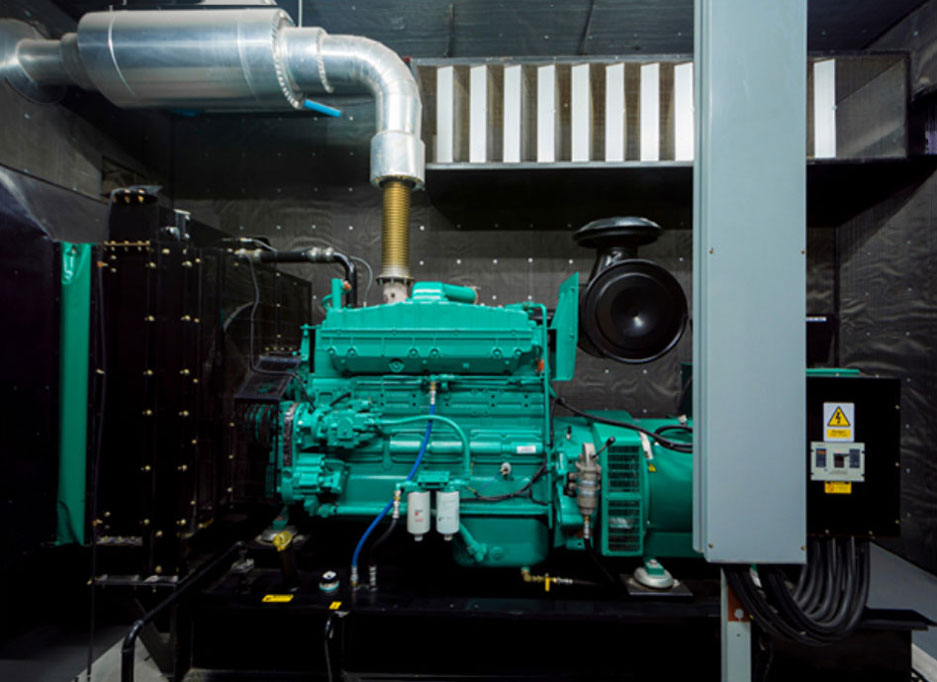

Fuel Efficient Generators for Electricity

Fuel-efficiency is one of our key considerations at NDL, state of the art 1166 KW power generators are being used at our manufacturing facility, stepping down our carbon footprint to lowest as possible. NDL is committed to increase power generation in future to fulfill energy requirements while keeping Environment clean as possible.

Replace conventional Lights with LED Lights for Energy Saving

From 40KW, down to 9KW only, NDL has dramatically reduced its power requirements for lights at manufacturing facility by replacing all standard lighting system to advanced LED lights. Further, all air-conditioning units are converted from AC Electricity to DC VRF Inverter, saving 94KW of electric power.

Heat recovery system at Rope Dyeing

In order to reduce carbon footprint to lowest as possible, NDL manufacturing uses Heat Recovery system at Rope Dying process, where 2 Tons of generated steam is stored and routed back to Rope Dying process making our facilities less energy dependent and reducing carbon emission.

Solar Energy System

Investing in renewable, NDL is implementing state of the art Solar Energy system which will generate 1.3 Mega Watts at initial stage. With a Goal to eliminate fuel dependency, Solar power will soon energize NDL's Manufacturing plant as well as Head Office Building.

Wind Power Energy System

Taking advantage of one of the fastest growing energy source, NDL is investing in Wind Power generation. Starting at 50 Mega Watts, NDL is installing wind power farms in Pakistan to reduce dependency on national power grid, making NDL the most sustainable denim manufacturer in country.